|

Cutting Acute Angles:

Dear Concord Carpenter,

I am doing the exterior cladding and trim on dormers.The roof pitch is 9/12.I am having a problem with finding and cutting the panel molding angles.

They are acute angles.I do not know how to find the angles or hot to cut such angles. I am using 4X8 panels with 1X4 trim

and panel molding.

I do not know how to cut the molding.

Thank you, James Scisciani

Dear James,

There are many times that I find I need cut trim or molding at an angle greater than my miter saw was designed for.

Most miter saws cut to 45 degrees or slightly larger, usually 50 degrees.

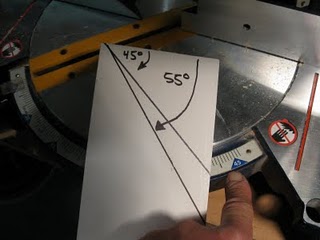

But what if you need to cut 55 degrees or a greater angle?

One very dangerous way is to hold the piece to be cut perpendicular to the saws fence and freehand this cut. I do not recommend cutting trim this way.

A safer solution is to make an acute angle cutting jig and keep it with your saw. I made this one out of scrap wood.

I arbitrarily chose 12" x 12" for this jig. I cut a 12" x 12" piece of 3/4" plywood and then cut it diagonally to make a brace for this jig.

Scrap 5/4 trim makes up the edges. I chose 5/4 sides because the raised edges give me plenty of space to clamp or screw this jig to my miter saw table.

I clamped and screwed the parts together at 90 degrees.

The goal here is to make an auxiliary fence jig that can be clamped or screwed to my miter saw fence. Below checking for square. [90degrees]

A bar and spring clamp hold the jig to my miter saw fence for a trial fit.

Trying out just spring clamps... quicker but not as strong as a bar clamp. I'm getting thirsty looking at that ice coffee in the background!!

Once the jig is secure the trim is held tight to the jig and the saw can be adjusted to much greater angles than if you used the saws fence.

Test cut at 55 degrees.

Dear Concord Carpenter,

I recently removed several radiators from my 300 year old home.

The floors are antique and I do not want to replace the floor boards if I don't have to as I may be unlikely to replicate the patina. Do you have any creative ideas on how I can fill the floor holes left by the absent radiators?

Thanks for your earlier help!

Dominique R

Dear Dominique,

Do you have any similar extra flooring in the basement, attic or

barn?

If you do you can use it or similar new wood of similar species

to patch your floor. I have done this dozens of times with huge

success.

Patching Holes In Hardwood Floors:

Here's what you do:

1. Use similar to match your flooring

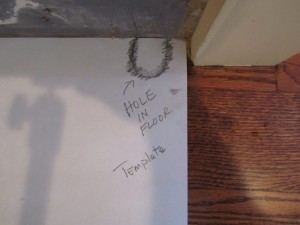

2. Trace your existing hole. I use paper over the hole and then use a pencil to lightly trace over the hole.

3. Transfer your pattern to the wood patch

4. Cut your wood with a band saw or jigsaw. Cut your patch or plug with a slight taper.

5. Use a random orbital sander with 80 grit paper to fine tune the wood patch until you have a perfect fit.

6. Use glue and and hammer to tap the patch into the hole.

7. Sand flush - use a sharp chisel and micro sanding on the patch if you don't want to scratch the surrounding flooring.

8. Mix stain to blend the patch to the existing floor.

|